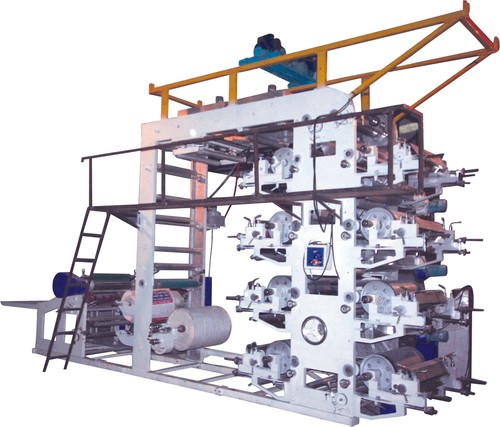

Roll To Roll Flexographic Printing Machine

Price 1050000 INR/ Piece

MOQ : 1 Piece

Roll To Roll Flexographic Printing Machine Specification

- Product Type

- Roll To Roll Flexographic Printing Machine

- General Use

- Industrial

- Computerized

- No

- Automatic

- Yes

- Voltage

- 220-440 Volt (v)

- Feature

- Lower Energy Consumption, High Efficiency

Roll To Roll Flexographic Printing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Roll To Roll Flexographic Printing Machine

Product Details:

| Minimum Order Quantity | 1 Unit |

| Usage/Application | Paper |

| Brand | mohindra |

| Material | Iron |

| Number Of Colors | 8 |

| Brand/Make | mohindra |

| Max Printing Length | 500-1000 (mm) |

| Machine Type | Automatic |

| Color Printing | Color Printing |

| Maximum Cutting Speed | 100 - 500 mm/sec |

| Weight | 10 ton |

| Capacity | 80 m/min |

| Phase | 3 |

| I Deal In | New Only |

| Maximum Cutting Speed (mm/sec) | 80-100 mm/min |

| Max Printing Length (mm) | 1000-1500mm |

We are offering Roll To Roll Flexographic Printing Machine to our clients.

Technical Specifications:

- No. Of Colours: 1 To 8

- Web Width: 500mm To 2050mm (20 To 80)

- Unwind/ Rewind Reel Dia: 1000mm (40)

- Unwind/ Rewind Core Id: 76mm And 152mm

- Range Of Cylinder Circumference: 250mm 1270mm (10 To 50)

- Printing Speed: 80 Mtr Per Min (variable As Per No. Of Colours Of Machine)

- Power Requirement: 4 Colour Machine: 16 Kw.

- 6 Colour Machine: 20 Kw.

- 8 Colour Machine: 24 Kw.

- Floor Space Length: Variable As Per The Machine

- Material That Can Be Printed: Hm, LD, Nonwoven, LIDPE, Paper Polyester Film, Foil Etc

- Available Models: 2,4,6,anad 8 Colours

- Web Width: 500mm To 2050m

- Reverse Printing Arrangement

- Top Drying Hood System And Intermediate Drying Between Units

- Heavy Duty Cast Iron Body (vibration Free)

Efficient and Eco-Friendly Printing

Our Roll To Roll Flexographic Printing Machine delivers impressive output with minimal energy usage, making it a cost-effective and sustainable choice for industrial production environments. The automatic functions enhance usability and workflow without the need for complex computerized systems, streamlining operations for manufacturers handling high-volume tasks.

Reliable Production Performance

Built for enduring reliability, these machines handle consistent, long-duration printing jobs while maintaining quality. The voltage flexibility (220440V) supports various industrial setups, and the straightforward controls ensure ease of use. The system is suitable for multiple substrate types, supporting diverse print applications.

FAQs of Roll To Roll Flexographic Printing Machine:

Q: How does the Roll To Roll Flexographic Printing Machine improve production efficiency?

A: The machine features automatic operations that streamline the printing process, minimizing manual intervention and maximizing output speed. Its design supports continuous roll-to-roll production, enabling high-volume printing with reliable consistency.Q: What are the main benefits of lower energy consumption for industrial users?

A: Lower energy consumption directly reduces operational costs, making the printing process more affordable and environmentally friendly. This machine is engineered to deliver optimal performance while using less electricity, particularly beneficial for large-scale printing facilities.Q: When is this printing machine typically used in industrial settings?

A: It is commonly employed when manufacturers require high-frequency, long-run printing jobs, such as packaging, labels, and flexible materials, where efficiency and energy savings are crucial.Q: Where can I source the Roll To Roll Flexographic Printing Machine in India?

A: You can purchase this machine directly from established exporters, manufacturers, and suppliers headquartered in India, who provide sales, support, and installation services domestically and abroad.Q: What is the operating process for this automatic flexographic printing machine?

A: The machine automates the roll feeding, printing, and rewinding stages. Operators load the substrate roll, set parameters, and the system manages the sequence with minimal manual intervention, resulting in efficient, continuous workflow.Q: How does the absence of computerized controls affect usage and maintenance?

A: With no computerized controls, operation and troubleshooting are straightforward, reducing training time and minimizing potential technical issues. Maintenance can be handled more easily by technicians familiar with non-digital systems.Q: What voltage range does the machine support, and why is it important for industrial users?

A: The machine accommodates a voltage range of 220440V, providing adaptability for various industrial power setups and ensuring compatibility with diverse electrical infrastructures.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Roll To Roll Flexographic Printing Machine Category

Single Colour Flexo Printing Machine

Price 1150000 INR / Piece

Minimum Order Quantity : 1 Unit

Printing Speed : 100 m/m

Printing Material : Kraft Paper

Control System : PLC Control

Printing Width : 20 inches Inch (in)

Eight Colour Flexo Printing Machine

Price 1150000 INR / Piece

Minimum Order Quantity : 1 Piece

Printing Speed : 100 m/m

Printing Material : BOPP

Control System : PLC Control

Printing Width : 20 inches Inch (in)

|

MOHINDRA MECHANICAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry