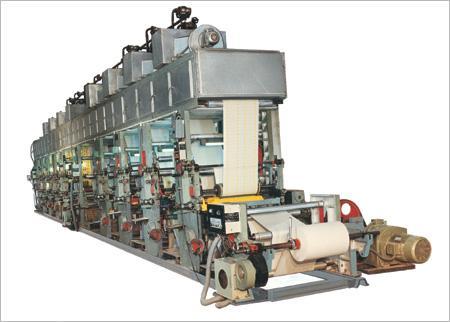

BOPP Film Printing Machine

BOPP Film Printing Machine Specification

- Type

- Printing Machine

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Automatic

- Voltage

- 280-420 Volt (v)

- Weight (kg)

- 4-6 Tonne

BOPP Film Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- Unit

- Delivery Time

- 45-60 Days

- Main Export Market(s)

- Western Europe, Asia, Australia, Eastern Europe, Middle East, Central America, Africa, South America, North America

- Main Domestic Market

- All India

About BOPP Film Printing Machine

Serving the domain from many years, we are a reputed manufacturer, exporter and supplier of a broad spectrum of BOPP Film Printing Machine. Highly acclaimed for its superior functionality, the provided machine is widely used in textile and paper industry. This machine is meticulously manufactured under the guidance of our dexterous team of experts using excellent grade components and advanced techniques as per the standards penciled by the industry. Offered in several models and other technical specifications, the provided BOPP Film Printing Machine can be availed from us at pocket friendly prices.

Features:

- Saves ink and ensure clear printing

- Ensures easy installation and high in performance

- Requires low maintenance over a long period of time

- User friendly design ensures effortless functionality

- Consumes minimum energy for its smooth operations

Specifications

- Printing material: - Film, paper, aluminum foil, pet, bopp, pvcfilm, polyster, bolyster, poly, matelized film etc

- Number of colors: - 1 - 8 colors

- Web Width:- 20" to 80"

- Web roller:- Aluminum rollers or steel rollers

- Machine speed:- Up to 250 m/min

- Unwind type: - Single fixed shaft type or 2 shaft turret type unwind

- Reel diameter: - 1000 mm(approx)

- Unwind shaft: - Air shaft, tapper cone with solid shaft or shaft ness

- Tension controller: - Manually & auto registration control system (A.C. Motor)

In feed unit:-

- Synchronized control (A.C. Motor)

Printing Unit:-

- Frame:- Cast iron

- Cylinder :- Diameter - 100 mm to 300 mm

- Chucking :- Shaft with taper cone

- Drying system :- Single chamber impingement slot dryer (electric, thermic oil, hot air generator, etc.)

- Doctor Blade :- Manual &numetic doctor blades

- Ink system :- S. S. ink tray

- Registration system:- Manually & auto registration control system

- Out feed unit:- Synchronized control (A.C. Motor)

Rewinder:-

- Reel diameter :- 1000 mm(approx)

- Rewind shaft :- Air shaft, taper cone with solid shaft or shaft ness

- Tension controller :- Manual & Fully automatic control system (A.C. Motor)

Efficient Automatic Printing

Engineered for convenience, this BOPP Film Printing Machine operates with a fully automatic grade. The intelligent system minimizes manual intervention, supporting seamless production lines for packaging businesses. Its flexible voltage compatibility enhances utility in diverse industrial environments, while the absence of computerized controls simplifies maintenance and operation.

Durable and Industrial Grade Construction

Manufactured with premium mild steel, the machine ensures longevity and resilience under continuous operation. Designed and built by seasoned exporters, manufacturers, and suppliers in India, it is suitable for rigorous industrial use, meeting the demands of high-volume printing on BOPP films for varied packaging needs.

FAQs of BOPP Film Printing Machine:

Q: How does the automatic BOPP Film Printing Machine operate without computerized controls?

A: This machine functions using a straightforward mechanical control system, allowing for easy setup and management. The automatic grade automates essential operations such as feeding, printing, and winding, reducing dependency on digital mechanisms.Q: What materials can the BOPP Film Printing Machine handle?

A: The machine is specifically designed to print on BOPP (Biaxially Oriented Polypropylene) films, which are widely used in packaging industries. Its robust mild steel construction ensures steady performance with these materials.Q: When is the ideal time to use this machine in your production process?

A: The machine is best utilized during the film printing phase, right before packaging and assembly of products. Its automatic operation makes it suitable for continuous, large-scale production environments.Q: Where is this printing machine primarily exported, manufactured, and supplied?

A: This BOPP Film Printing Machine is manufactured, supplied, and exported from India, catering mainly to clients and businesses in regions demanding high-quality packaging film printing solutions.Q: What is the installation process for this machine?

A: Installation involves electrical connection within a voltage range of 280420 volts, placement in a suitable industrial space due to its 46 tonne weight, and basic mechanical setup as per the manufacturers guidelines.Q: How is this machine beneficial for industrial packaging operations?

A: It streamlines printing tasks with its automatic features, minimizes manual intervention, ensures consistent print quality, and helps meet large-scale demands efficiently, leading to increased productivity and reduced errors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rotogravure Printing Machine Category

Multicolour Rotogravure Printing Machine

Price 600000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Mild Steel

Computerized : No

Aluminium Foil Printing Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Blister foil, Labels, PVC, Aluminium Foil, PVCC, Laminated Foil, BOPP, Paper, Pet, etc.

Width : 20" to 80" Inch (in)

Computerized : Yes

Aluminium Foil Printing Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Blister foil, Labels, PVC, Aluminium Foil, PVCC, Laminated Foil, BOPP, Paper, Pet, etc.

Width : 20" to 80" Centimeter (cm)

Computerized : Yes

Pharma Printing Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Blister foil, Labels, PVC, Aluminium Foil, PVCC, Laminated Foil, BOPP, Paper, Pet, etc.

Width : 20" to 80" Inch (in)

Computerized : Yes

|

MOHINDRA MECHANICAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry