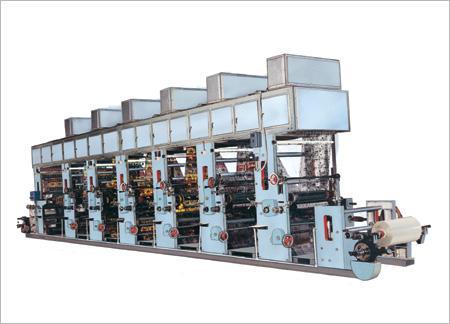

Rotogravure Printing Machines

Price 600000.0 INR/ Piece

Rotogravure Printing Machines Specification

- Type

- Rotogravure Printing Machines

- Material

- bopp, polyester, aluminum foil, pp, poly, paper etc

- Computerized

- No

- Automatic Grade

- Automatic

- Printing Color

- Multicolor

- Printing Width

- 20" to 80" Inch (in)

- Voltage

- 380-440 Volt (v)

- Warranty

- 1 Year

Rotogravure Printing Machines Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Rotogravure Printing Machines

Rotogravure Printing Machine is used in flexible packaging manufacturing and printing process including polyester, Nylon, BOPP, Foil, low and high density polyethylene polypro plane and paper with two sided printing facilities with high speed hot air dryers. The high speed rotogravure printing machine has the great flexibilities and high resolution color combination at faster rate. The rotogravure printing machine is well designed for precision engineering for best industry standard requirements of valued clients with technical excellence, easy machine operations with good efficiency and performance, high durability and reliability with standard parts made from sturdy materials.

Rotogravure printing machine is designed to support flexible packaging film manufacturing industry. Rotogravure print plant is an expert supplementary solution that can be added to the existing flexible packaging film plant as it can print on variety of materials including paper, flexible films, aluminum foils, etc. Rotogravure printing line is a suitable choice to print on lamination lines made of different ingredients. Investing on this supplementary machine is a favorable opportunity to reduce the cost of secondary packaging requirements.

The first step of Gravure is to create the cylinder with the engraved images that need to be printed: the engraving process will create on the cylinder surface the cells that will contain the ink in order to transfer it to the paper. Since the amount of ink contained in the cells corresponds to different colour intensities on the paper, the dimensions of the cells must be carefully set: deeper cells will produce more intensive colours whereas less deep cells will produce less intensive ones. There are three methods of photoengraving that have been used for engraving of gravure cylinders, where the cell open size or the depth of cells can be uniform or variable.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rotogravure Printing Machine Category

Multicolour Rotogravure Printing Machine

Price 600000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Mild Steel

Foil Printing Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Blister foil, Labels, PVC, Aluminium Foil, PVCC, Laminated Foil, BOPP, Paper, Pet, etc.

Printing Width : 20" to 80" Inch (in)

Width : 20" to 80" Centimeter (cm)

Foil Printing Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Blister foil, Labels, PVC, Aluminium Foil, PVCC, Laminated Foil, BOPP, Paper, Pet, etc.

Printing Width : 20" to 80" Inch (in)

Width : 20" to 80" Inch (in)

Poly Printing Machine

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Mild Steel

|

MOHINDRA MECHANICAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry