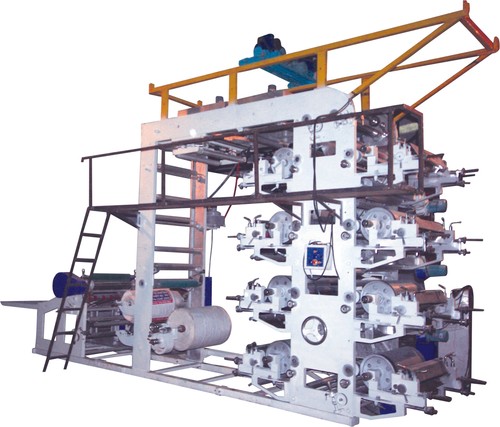

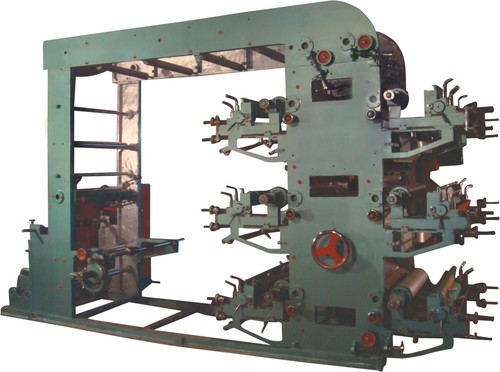

8 Colour Flexographic Printing Machine

Price 1150000 INR/ Piece

8 Colour Flexographic Printing Machine Specification

- Product Type

- 8 Colour Flexographic Printing Machine

- General Use

- Industrial

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Control

- Printing Width

- 20 inches Inch (in)

- Voltage

- 380-440 Volt (v)

- Color

- 2 to 8

8 Colour Flexographic Printing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About 8 Colour Flexographic Printing Machine

Advanced PLC Control System

This flexographic printing machine features a robust PLC control system for enhanced process automation and consistent print quality. Operators can easily adjust settings, monitor operations, and ensure accurate color registration.

Flexible Color Options

Choose between 2 to 8 color configurations for versatile printing demands. This flexibility allows businesses to cater to varied customer requirements, producing vibrant and detailed prints for packaging and labels.

Industrial-Grade Performance

Engineered for industrial environments, the machine supports a generous printing width of 20 inches. It is suitable for large-scale production, delivering durable and high-speed output for manufacturers, exporters, and suppliers.

FAQs of 8 Colour Flexographic Printing Machine:

Q: How does the PLC control system benefit the flexographic printing process?

A: The PLC control system automates key functions, ensuring precise adjustments and consistency in print quality. It streamlines operations and minimizes human error, improving overall efficiency.Q: What materials can the 8 Colour Flexographic Printing Machine print on?

A: This machine is suitable for a range of industrial materials including films, packaging paper, and flexible substrates commonly used in labeling and packaging applications.Q: When is it recommended to use this machine with full 8-color capability?

A: Full 8-color capability is ideal for projects that require complex, vivid designs or detailed graphics, typically in premium packaging or promotional print jobs.Q: Where is this printing machine primarily used?

A: The machine is primarily utilized in industrial settings such as manufacturing plants, packaging facilities, and printing firms across India.Q: What is the process for adjusting printing width on this device?

A: Operators can easily set the printing width up to 20 inches by adjusting built-in guides and PLC-controlled settings before starting a new job.Q: How does automation improve the usage of the machine for suppliers and exporters?

A: Automation through PLC controls offers suppliers and exporters faster turnaround times, reduced manual intervention, and consistent product quality, crucial for meeting large order demands.Q: What are the key benefits of using this flexographic printing machine?

A: The machine provides reliable, high-speed performance, flexible color configurations, and precise control, allowing businesses to efficiently handle a variety of printing tasks with minimal downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flexo Printing Machine Category

PP Non Woven Fabric Printing Machine

Price 1150000 INR / Piece

Minimum Order Quantity : 1 Piece

Printing Speed : 100 m/m

Automatic : Yes

Control System : PLC Control

Printing Width : 20 inches Inch (in)

Woven Bag Printing Machine

Price 1150000 INR / Piece

Minimum Order Quantity : 1 Piece

Printing Speed : 100 m/m

Automatic : Yes

Control System : PLC Control

Printing Width : 20 inches Inch (in)

HDPE Bag Printing Machines

Price 1150000 INR / Piece

Minimum Order Quantity : 1 Piece

Printing Speed : 100 m/m

Automatic : Yes

Control System : PLC Control

Printing Width : 20 inches Inch (in)

Non Woven Bags Printing Machine

Price 1150000 INR / Piece

Minimum Order Quantity : 1 Piece

Printing Speed : 100 m/m

Automatic : Yes

Control System : PLC Control

Printing Width : 20 inches Inch (in)

|

MOHINDRA MECHANICAL WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry